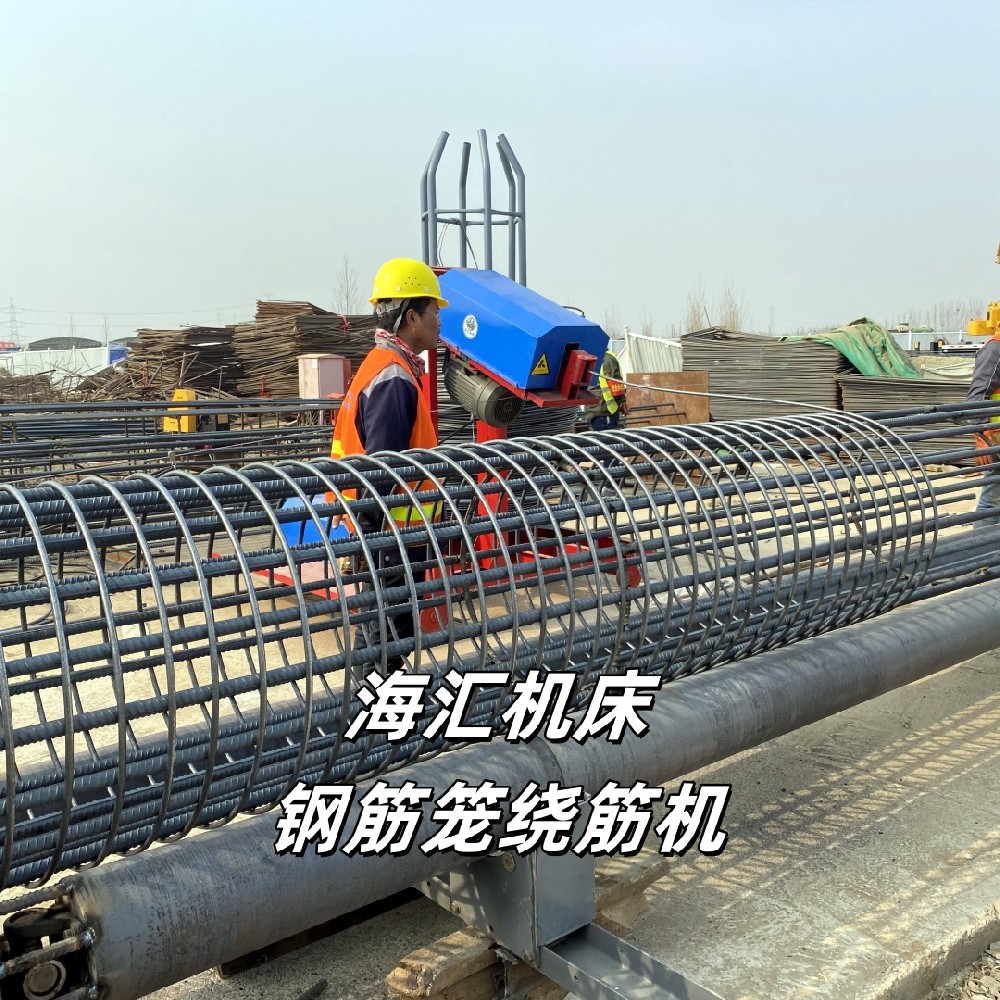

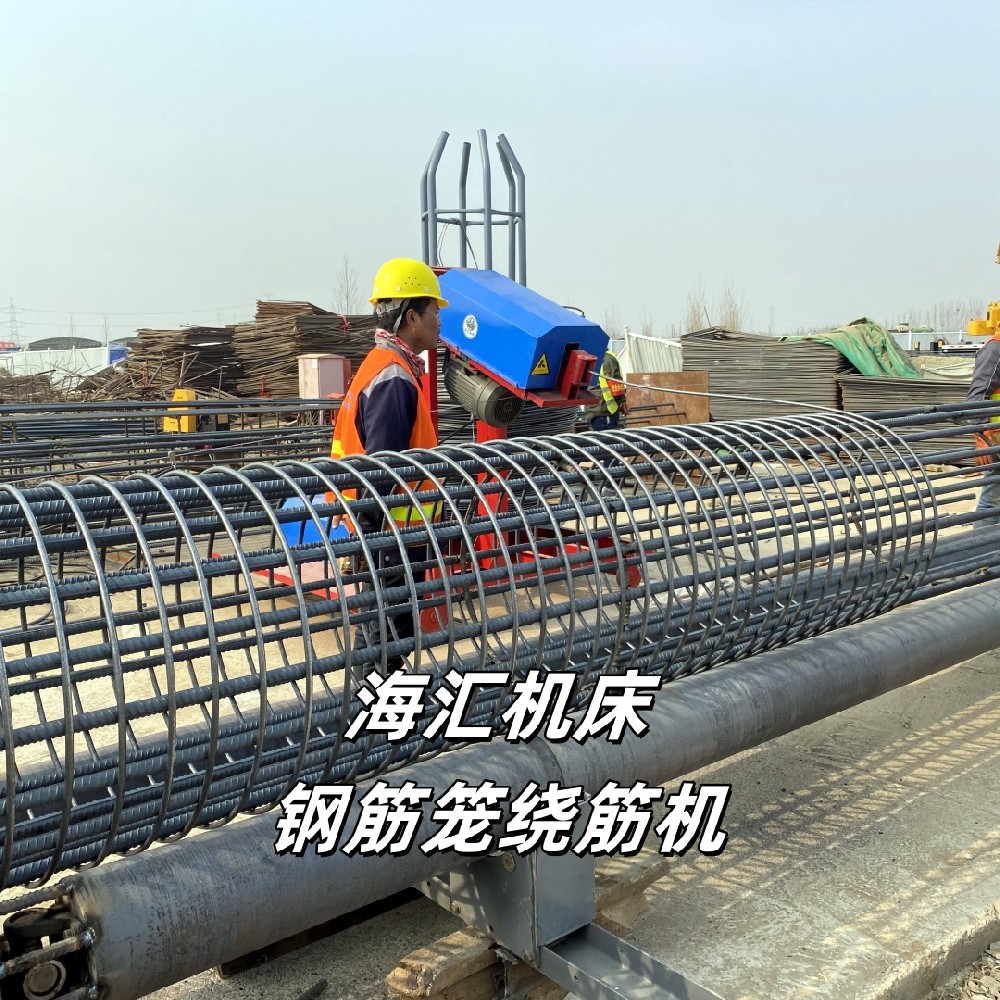

Bridge construction site actual shooting: the entire process of steel cage winding machine operation

In the bustling world of bridge construction, the steel cage winding machine stands out as a crucial piece of equipment. Its operation is a complex yet fascinating process that plays a vital role in ensuring the structural integrity of bridges. Here is a detailed look at the entire process of steel cage winding machine operation on a bridge construction site.

Equipment Inspection: Before starting the steel cage winding machine, a comprehensive inspection of the equipment is essential. Check the main components of the equipment to ensure they are installed correctly and securely. Examine the electrical circuits for any abnormalities, and make sure to turn on the main power switch only after confirming everything is in order. Also, check the air pressure in the pneumatic system to ensure it meets the required standards.

Parameter Setting: Set the parameters according to the specific requirements of the steel cage to be produced. This includes setting the pitch of the steel cage, the speed of the rotating discs, the welding time, and the lifting and lowering parameters of the cage support device. These parameters need to be accurately configured to ensure the quality of the steel cage.

Material Preparation: Place the semi-finished main reinforcement bars on the reinforcement support frame. Select the appropriate turntable mold according to the diameter of the steel cage and install it on the cross rib frame of the fixed and movable turntables. Install the reinforcement penetration tubes and fixation sleeves. Thread the main reinforcement bars through the penetration tubes of the fixed disc and insert them into the fixation sleeves of the movable disc. Tighten the bolts to secure the reinforcement bars.

Feeding of Stirrups: Pass the end of the stirrup through the feeding guide roller and weld it to one of the main reinforcement bars. This initial step secures the starting point of the stirrup winding process.

Winding and Welding: Turn on the manual or automatic button. The movable turntable rotates and moves simultaneously, winding the stirrup around the main reinforcement bars. As the stirrup is being wound, manual welding (CO₂ automatic shielded welding) is carried out to connect the stirrups and the main reinforcement bars, forming the steel cage structure.

Length Control and Support: As the steel cage reaches a certain length, the corresponding cage support devices lift up one by one to support the steel cage. This ensures the stability of the steel cage during the winding process. When the steel cage welding reaches the predetermined length, stop the welding and press the corresponding stop buttons of the cage support devices to lower all the supports.

Product Removal: After the steel cage is completed, carefully remove the finished product from the machine. Handle it with care to avoid damaging the steel cage structure.

Equipment Cleaning: Clean the steel cage winding machine to remove any remaining debris or welding slag. This helps to maintain the performance and lifespan of the equipment.

Maintenance and Inspection: Conduct a routine maintenance check on the equipment. Check for any loose parts, wear and tear, or other potential problems. Lubricate the relevant parts to ensure smooth operation for the next use.

In conclusion, the operation of the steel cage winding machine on the bridge construction site is a systematic process that requires strict compliance with operating procedures and careful attention to detail. Each step is crucial in ensuring the production of high-quality steel cages, which in turn contribute to the safety and durability of the bridge structure.

WeChat scan code

WeChat scan code